Neodymium magnets are strong magnets,frequently used for many types of sectors, commercial, industrial & technical applications where strong permanent magnets are required. Due to their high-magnetic strength, components that previously had to be large and heavy can now be miniaturized by using Neodymium magnet material.

· Common Applications: holding systems requiring very high holding forces, sensors, reed switches, hard disc drives, audio equipment, acoustic pick-ups, headphones & loudspeakers, MRI scanners, magnetically coupled pumps · motors & generators, magnetic tool holders, magnetic bearings, door catches, dental instruments, medical devices, magnetic separators, lifting machinery, crafts & model making, hanging artwork, levitation devices, POP displays, commercial signage, packaging closures, jewelry clasps & more.

U-Polemag can make large inventory of Neodymium magnets in disc, block, rod , ring , arc & customized irregular shapes, in a wide range of shapes, sizes and grades. Just let us know what you are looking for by sending us a request for quote or contact us to discuss your specialty project.

Samarium Cobalt (SmCo) magnets ,a type of rare earth magnet, is a strong permanent magnet made of two basic elements samarium and cobalt. They are available in two "series", namely SmCo5 magnets and Sm2Co17 magnets. SmCo magnets have excellent temperature stability while maintaining their magnetic properties for applications involving extreme temperature conditions. Because of their unique attributes, SmCo magnets are ideally suited for technical applications where high-performance is critical, strong magnetic strength is required, and space is a limiting factor. Commonly used in the automotive, aerospace, medical, military, industrial manufacturing, semiconductor, wind, power, oil and energy industry.

· Common Applications: high-performance permanent magnet motors, actuators, generators, turbo machinery, electric motors, magnetic separation devices, traveling wave tubes, magnetic couplings, magnetic bearings, sensor systems, energy recovery systems, medical devices, missile components, industrial automation equipment, pipeline inspection and drilling equipment, wind turbine equipment, robotic arms, gyroscopes, accelerometers, particle accelerators, sputtering deposition, halbach arrays, drive components & more.

Welcome to contact us to discuss your specialty requirements.

Alnico magnets are relatively high in magnetic strength, offer excellent temperature stability and can be used in temperatures up to 1000°F (500°C), making them the preferred choice for many industrial applications. Alnico magnets are manufactured through a casting or sintering process, so they can be made into complex shapes, not possible with other magnet materials. Commonly used in the oil and gas, medical, aerospace, miltary and defense, industrial automation, automotive, and manufacturing industry.

· Common Applications: guitar pickups, electrical motors, bearings, traveling wave tubes, aerospace equipment, rotating machinery, sensors and sensing devices, communications, meters and instruments, harsh environment equipment, high temperature handling equipment, heat treatment jigs, medical devices, industrial machinery, microphones, robotics arms, industrial automation equipment, actuators, military radar equipment, magnetors, security systems & more.

Welcome to contact us to discuss your specialty requirements

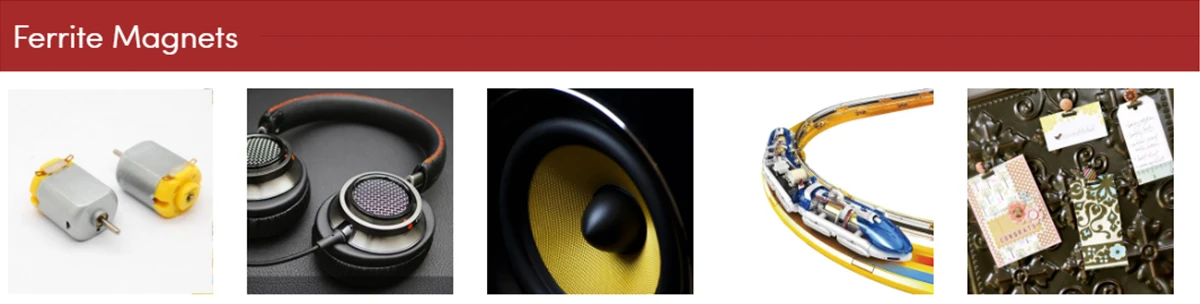

Ferrite (Ceramic) magnets are the lowest cost hard magnets available today, it is a ceramic material made by mixing and firing large proportions of iron oxide (Fe2O3, rust) blended with small proportions of one or more additional metallic elements, such as barium, manganese, nickel, and zinc.They are both electrically non-conductive, meaning that they are insulators, and ferrimagnetic, meaning they can easily be magnetized or attracted to a magnet. Ferrites can be divided into two families based on their resistance to being demagnetized (magnetic coercivity).

Ferrite compounds are extremely low cost, being made of mostly rusted iron (iron oxide), and have excellent corrosion resistance. They are very stable and difficult to demagnetize, and can be made with both high and low coercive forces.

· Common Applications: lifting applications, school projects, loudspeakers, guitar pick-ups, eddy current devices, breaks and clamps, motors, generators, switches, relays, security systems, sweeper magnets, crafts and model making, DIY projects, science experiments, classroom displays, store displays, lifting machinery, apparel, office display boards, home or office organization, promotional gifts and more.

Welcome to contact us to discuss your specialty requirements.

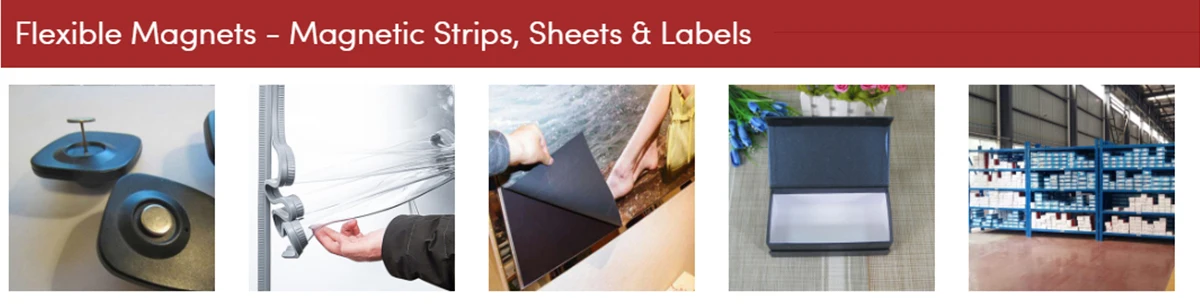

Flexible Magnets are used for hundreds of consumer and commercial applications as it’s easy to use, easy to customize and easily adheres to other items. Flexible magnet material can be bent, twisted, coiled, or cut with scissors and utility knives. Flexible magnetic sheets and strips can be printed, silkscreened or painted with permanent and erasable markers.

Ferrite compounds are extremely low cost, being made of mostly rusted iron (iron oxide), and have excellent corrosion resistance. They are very stable and difficult to demagnetize, and can be made with both high and low coercive forces.

· Common Applications: warehouse organization, labeling projects, POP displays, crafting projects, toys, games, window and door seals, promotional giveaways, business cards, packaging closures, vehicle signs, trade show displays, badge holders, masking areas for painting, large format graphics, model making, store displays, office presentationa, DIY home improvement projects, commercial signage, fridge magnets, packaging solutions & more.

Welcome to contact us to discuss your specialty requirements.

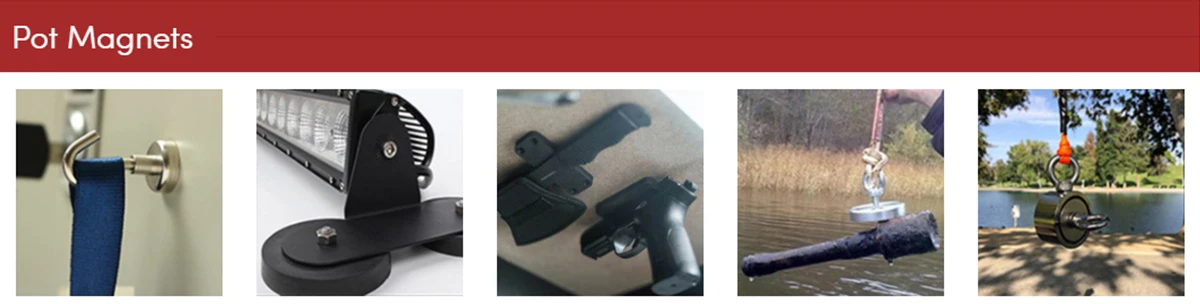

Pot magnet is a simple magnet system with super-strong magnetic force. The permanent magnets are affixed into a durable steel cup or channel. This makes a magnetic shielding area and then focuses all magnetic force on one side of magnet. So the pull force of pot magnet is bigger than plain permanent magnet and can hold heavier objects. We offer different types - from countersunk pot magnet over magnet base with thread to magnet systems with rubber coated and hard ferrite cup magnets. This allows you to select the products that best fit your needs.

· Common Applications: They are suitable as cup magnets, magnet base, outdoor attachments for holding/mounting/fixing application at home or at work as well as in industry or for craft, hobby and leisure. Such as position or hold or mount inspection equipment, indicator gauges, car lamps, work LED, signs, exhibit fixtures, tools, antennas and more. Pot magnets feature countersunk holes or threaded features that allow for different mounting methods, no matter standard hardware (nuts and bolts), or various hooks.

Welcome to contact us to discuss your specialty requirements.

The Magnetic Knife Holder also named Magnetic Knife Bar , Magnetic Knife Strips or Magnetic Knife Rack have many different names but only one purpose that to hold your knives save in place wherever you mount it.U-POLEMAG offer stainless steel magnetic knife holders, wood magnetic knife holders, marble magnetic knife holders, various styles and materials for meeting your individual requirements. U-Polemag not only give you an unique way to store your cutlery and utilize space well, also it’s an attitude of high quality life.

U-Polemag magnetic tools family include magnetic tool holders , magnetic pin bowls, magnetic sweepers, magnetic welding clamps ,magnetic wrist and so on. This is a big family, our R&D engineers are busy researching new products for meeting customers’ requirements and we also would like accept OEM according to customers’ request ,our advantages : we know magnets very well and we are integrated, versatile and powerful in production technology

U-Polemag can make versatile permanent Magnetic Separation Equipment for any application, widely used in the food, dairy, grain & milling, chemical, plastics, oil, textile, recycling, and other industries for applications and products similar to yours. We manufacture an extensive line of Magnetic Separation Equipment to remove metal contaminants from dry particulates, liquids, and slurry. You can rely on our equipment and expertise to eliminate product contamination and damage to machinery from tramp metal in an economical and cost-effective way.